Respirators

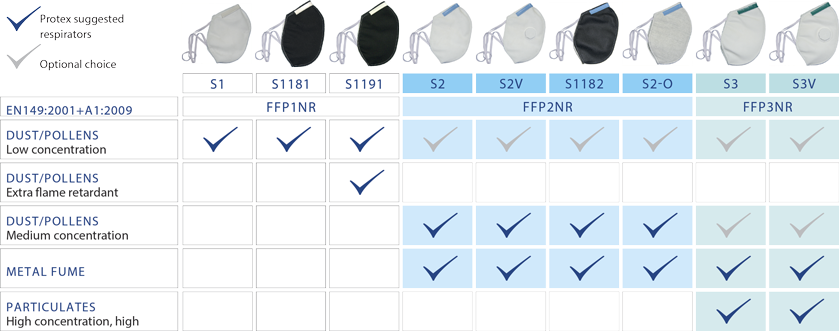

PROTEX Respirator selection guide

This guide is intended to help you select the appropriate Protex respirator for your application. You should only make your final selection however after you have assessed the level and type of protection required and have read the instructions on the packaging.

For further advice if required ring us on 0121 544 7117.

Protex Filtration System

All Protex Respirators meet EN149:2001+A1:2009

EN149 FFP1NR – ASSIGNED PROTECTION FACTOR 4

S1 and S1181 protect against particulate dusts, pollens and non volatile liquid particles. They are at least 75% effective against fine dusts and can be used for protection where the level of contamination is up to 4 times the Occupational Exposure Limit (OEL).

The latest version of the S1181 in black is manufactured with technologically advanced filtration material. The slim lightweight design creates an excellent fit with minimal breathing resistance, offering comfort and reliability.

S1 is its equivalent with white coverstock and S1191 is the flame retardant version in black.

EN149 FFP2NR – ASSIGNED PROTECTION FACTOR 10

S2 and S1182 protect against particulate dusts, fumes, pollens and non volatile liquid particles. They are at least 90% effective against fine dusts and can be used for protection where the level of contamination is up to 10 times the Occupational Exposure Limit (OEL).

S2V also meets these standards and has the addition of an exhalation valve. The Protex valve has been developed to further improve comfort, dispelling the heat, humidity and exhaled CO2.

S2-O respirator also meets EN149 FFP2NR and uses activated charcoal to remove nuisance levels of odour and organic vapour.

EN149 FFP3NR – ASSIGNED PROTECTION FACTOR 20

S3 protects against particulate dusts, fumes, pollens and non volatile liquid particles. It is at least 98% effective against fine dusts and can be used for protection where the level of contamination is up to 20 times the Occupational Exposure Limit (OEL).

These respirators meet the exacting requirements of EN149 FFP3NR whilst retaining the fit and comfort factors established by the Protex range. In many of the more demanding working environments the S3 has proved a technically advanced yet light, comfortable and cost effective solution.

S3V is the equivalent with an exhalation valve.

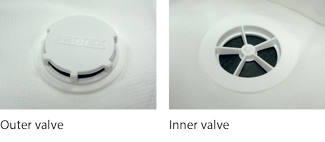

Protex Exhalation Valve

The Protex exhalation valve has been designed and tested to offer a combination of low inhalation and low exhalation resistance, the result being decreased temperatures inside the respirator. The valve dispels heat, humidity and exhaled CO2.

In more demanding work conditions the Protex valved option offers an improved working environment. Valved Protex respirators are available at EN149 FFP2NR and FFP3NR standards and are coded S2V and S3V.

Guidance

HSG 173).

2. Determine the Occupational Exposure Limit for the contaminant. (Health and Safety Executive Guidance Note Workplace Exposure Limits EH140/2005).

4. Refer to BS EN 529:2005 Respiratory protective devices. Recommendation for selection, use, care and maintenance Guidance Document which explains how to implement a programme for safe and effective use of respiratory devices.